810 Coil Winding Machine with 0.03 to 1.2mm Tensioner CNC Automatic Wire Winder Dispenser Dispensing Tools 400W 110/ 220V

- Brand: unbranded

- Product Code: CN230807300577

- Availability: 14400

Best 810 Coil Winding Machine with 0.03 to 1.2mm Tensioner CNC Automatic Wire Winder Dispenser Dispensing Machine 400W 110/ 220V

New Computer C Automatic Coil Winder Winding Machine for 0.03-1.2mm wire

if your place is remote ,then need to pay 35usd .

Specification for 810 winding machine

power voltage:single phase AC 220V 50HZ

Cop motor:three phase machine 400W(1/2hp)

winding displacement machine:step-servo motor

Brand:810

Spindle motor: Brushless DC

Numbers of cop:1

Windable wire gage:0.03-1.2mm

Maximum winding width:110mm

Maximum screw diameter:120mm

Maximum turning speed of cop:6000circles/minute,speed adjust function

Storable winding groups:999 groups

Counting resolution:0.1 circle

Complete appliance weight:30kg

Size:510*490*450mm

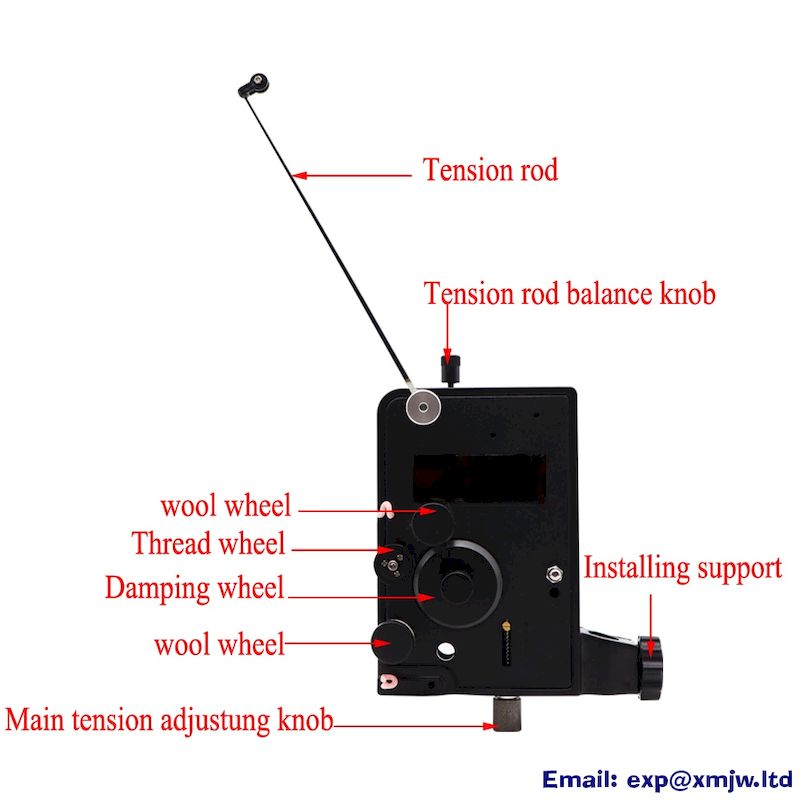

Description for Tensioner

The tensioner is the key component of the winding machine to produce adjustable tension when winding, so that the enameled wire is wound with proper tension, so that the wound coil is tight and tight, and the coil technical index is consistent.

Model | Wire range(mm) | Tension Range(g) | ||

TCSS-X | 0.03-0.06 | 7.0-30 | ||

TCSS-W | 0.03-0.08 | 6.0-50 | ||

TCS | 0.08-0.16 | 40-200 | ||

TCS-E | 0.06-0.13 | 20-130 | ||

TCM | 0.16-0.25 | 90-500 | ||

TCMM | 0.12-0.40 | 70-600 | ||

TCL | 0.2-0.6 | 200-2000 | ||

TCLL | 0.5-1.2 | 1000-5000 |

Feature for 810 winding machine

1.This series of automatic filament winder computer controller adopts the latest synchronous winding , it is with high precision and there will be no obstacles appear when in excessive speed winding displacement process .

2.Super elevated wisdom model , it has self-inspecting functions, including the errors of the equipments ,excessive speed tracking and the calibration of the speed.

3.Has vernier caliper functions and can measure the winding width and starting point easily.

4.The speed of the cop motor can be changed at random when in operation , and the strand oscillator also can synchronize with it.

5.After the startup of the cop motor , the time of speed growing can be changed at random depend on the type of the machines.

6.Obtain winding excessive speed detecting function , and it can reduce the winding speed automatically to the most steady state.

7.Can settle data: starting point, wire gage, winding displacement width, circles, speed of starting the winding , stopping slow-speed, winding speed, slow lathe speed , winding displacement direction , winding direction , two-terminal stopping , automatic reset, automatic start (job-hopping winding)

8.Foot-switch connection for better efficiency.

9.Winding parameters and options can be set independently for each step.

10.Memory capacity accommodates 999 steps of parameters with off-power memory retention.

Feature for Tensioner

1,The damping tensioner is a device that transmits a constant torque by using a field as a medium. The damper disc is not in contact with the and has no sliding friction, so the service life is long and the tension control is extremely stable.

2,The rotating parts are precision machined from a lightweight and sturdy material with minimal moment of inertia.

3,The tension output rubber wheel is made of elastic soft rubber and does not hurt the wire.

4,The metal parts are treated with anti-rust treatment and have excellent corrosion resistance.

5,Simple installation structure, convenient adjustment of tension, compact structure, compact size, stable operation in various positions

Tension adjustment method:

1,It is recommended to adjust the scale value to 3 or more. If the tension is too large at this time, it is better to use a small size damper.

2,If it is used below the scale value of 3, there may be a pulsation of force. Please eliminate the pulsation as described in item 3 below.

3,Loosen the fastening screw, turn the scale to 10, and slowly turn the scale to 0 while turning the spindle, then turn to the desired scale value. Tighten the locking screw.

4,If tension pulsation occurs during use, repeat the above steps of adjustment method 3 until a satisfactory tension is obtained.

5,The damper uses the to generate the medium field, and the material is brittle. Therefore, do not disassemble it during use to avoid damage to the machine.

Real photo shows

| Certification | CE |

| is_customized | Yes |

| Material | Steel |

| Maximum screw diameter | 120MM |

| Maximum winding width | 110MM |

| Model Number | 810 Wire Coil Machine |

| Origin | Mainland China |

| Type | Spiral Wrapping |

| Voltage | 220V/110V |

| Windable wire gage | 0.03-1.2mm |

Tags: Best 810 Coil Winding Machine, with 0.03 to 1.2mm Tensioner CNC Automatic Wire Winder Dispenser Dispensing Tools 400W 110/ 220V